The construction process of the wood grating background wall usually includes the following steps:

First, construction preparation

Material preparation:

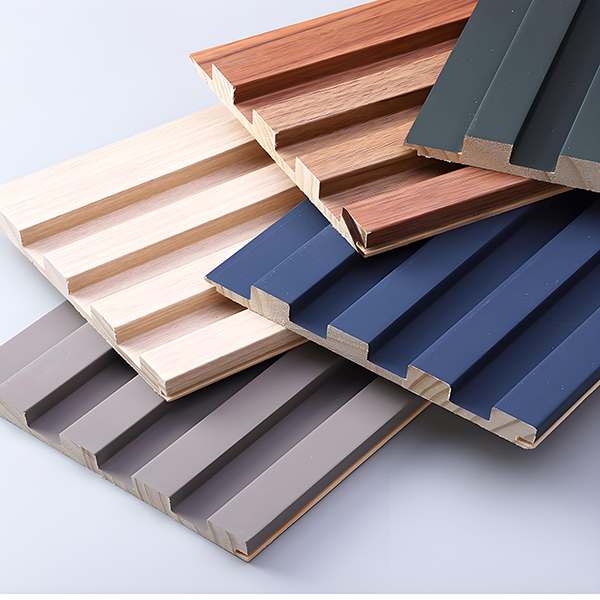

According to the design requirements, prepare solid wood grille plate, fixing screws, installation track (if necessary), structural glue (or marble glue), gun nails and other construction materials.

Ensure that the material, size, color, etc. of the wood grating plate meet the design requirements, and the commonly used materials are New Zealand pine.

Tools required:

Prepare construction tools such as the electric drill, screwdriver, cutting tool, measuring tool, level, and glue gun.

Basic treatment:

Ensure that the base layer of the background wall is smooth, dry and free of stains. If necessary, leveling treatment is performed.

Second, installation steps

Measurement and positioning:

Use measuring tools to accurately measure the size of the background wall and determine the installation position and spacing of the wooden grille plate.

Mark the location of the mounting track or fixing point on the background wall according to the design requirements.

Install track (if required) :

If you install the track, fix the track on the background wall first to ensure that the track is smooth and firm.

According to the specifications of the track and the size of the wooden grating plate, determine the position and spacing of the slats.

Fixed wooden grille plate:

If you do not install the track, you can directly use fixing screws or gun nails to fix the wooden grille plate on the background wall.

Before fixing, evenly apply structural glue (or marble glue) on the back of the wooden grille plate to enhance the fixing effect.

Use an electric drill or screwdriver to drive the fixing screws or gun nails into the grille to ensure that the grille is smooth and secure.

Splicing and closing:

According to the design requirements, a number of wooden grille plates are spliced to ensure that the splicing place is smooth and without gaps.

Use a closing strip or sealant to close the splice to improve the overall appearance.

Third, construction precautions

Safe construction:

In the construction process, to strictly abide by the safety operation procedures, wear good protective equipment.

When using tools such as electric drills and screwdrivers, ensure stable operation to avoid personal injury or material damage.

Quality control:

Strictly control the material, size, color and other quality elements of the wood grating plate to ensure that it meets the design requirements.

During the installation process, it is necessary to check the quality indicators such as the flatness and firmness of the wooden grille plate at any time to ensure the quality of construction.

Environmental requirements:

In the construction process, pay attention to the environmental protection of materials, avoid the use of harmful materials or produce harmful substances.

After the construction is completed, the site should be cleaned up in time to keep the environment clean.

Iv. Construction acceptance

Appearance inspection:

Check the overall appearance of the wood grating background wall to ensure that it is smooth, beautiful and without defects.

Check whether the splicing is smooth and seamless, and whether the closing treatment is in place.

Functional check:

Check whether the fixing of the wood grating background wall is firm and whether there is loosening or falling off.

According to the design requirements, carry out relevant functional tests to ensure that the use requirements are met.

Through the detailed introduction of the above construction process, I believe that you can easily complete the construction work of the wooden grating background wall. In the construction process, please be sure to pay attention to safe construction and quality control to ensure that the construction quality meets the design requirements.