Bamboo and wood fiber wallboard is a composite material processed by the following main materials and their auxiliary materials through a specific process:

Main material

Bamboo powder: Made from natural bamboo fiber, bamboo fiber is the fifth largest natural fiber after cotton, hemp, wool and silk. Bamboo powder has good air permeability, instant water absorption, flexibility, wear resistance, and natural antibacterial, insect, mite, odor and UV resistance functions. The special ultra-fine pore structure inside bamboo fiber makes it have strong adsorption capacity, can absorb formaldehyde, benzene, toluene, ammonia and other harmful substances in the air, and eliminate bad odor.

Wood flour: a new type of energy saving and environmental protection raw material, with warm, insulation, strong acid and alkali resistance, water resistance, corrosion resistance and other characteristics. The combined content of it and bamboo powder accounts for more than 70% of bamboo and wood fiber integrated wallboard. Wood fiber is a kind of natural plant cellulose fiber with both health and environmental protection. It has the characteristics of sun resistance, heat resistance, chemical resistance, melt resistance and mold resistance.

Light calcium carbonate: that is, lime, with good water absorption and insect protection effect, can enhance the hardness of the wall board.

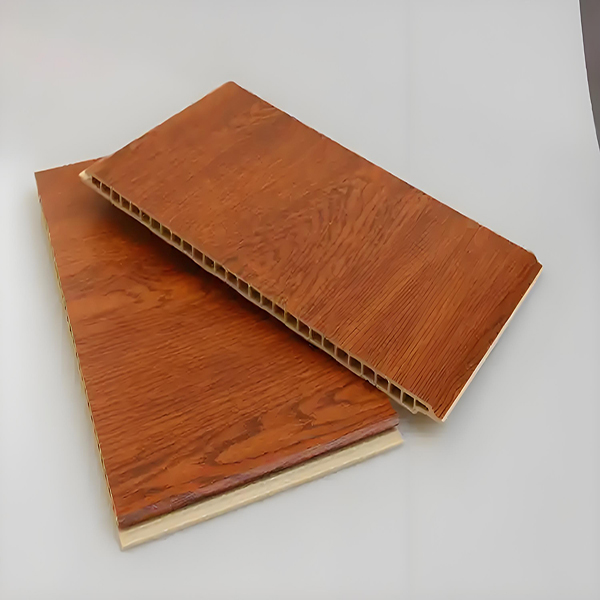

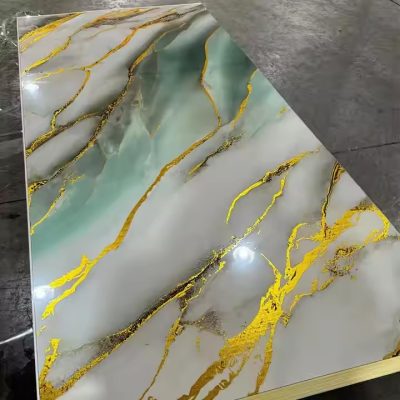

Polymer resin: usually refers to PVC, that is, polyvinyl chloride, used for wall panel surface coating. After being mixed with additives and plasticized, a transparent or colored film of specified thickness is formed by a three-roll or four-roll calendering mechanism, and the film processed by this method becomes a calendered film. After pressing at high temperature, the resin film is closely bonded with the plate, which does not fade, do not yellow and do not fall off.

Auxiliary material

In the production process, bamboo and wood fiber wallboard will also add flame retardants, waterproof agents, stabilizers, paraffin and other auxiliary materials to improve its performance.

Environmental protection property

Bamboo and wood fiber wallboard in the production process pay attention to environmental protection, the use of environmental protection adhesives, formaldehyde release is far lower than the national standard, and even can reach zero formaldehyde release level, and will not release volatile organic compounds (VOC), to avoid air pollution. Bamboo fiber itself is renewable, friendly to the environment, and bamboo fiber wallboard can be completely degraded, will not cause harm to the environment.

Processing technology

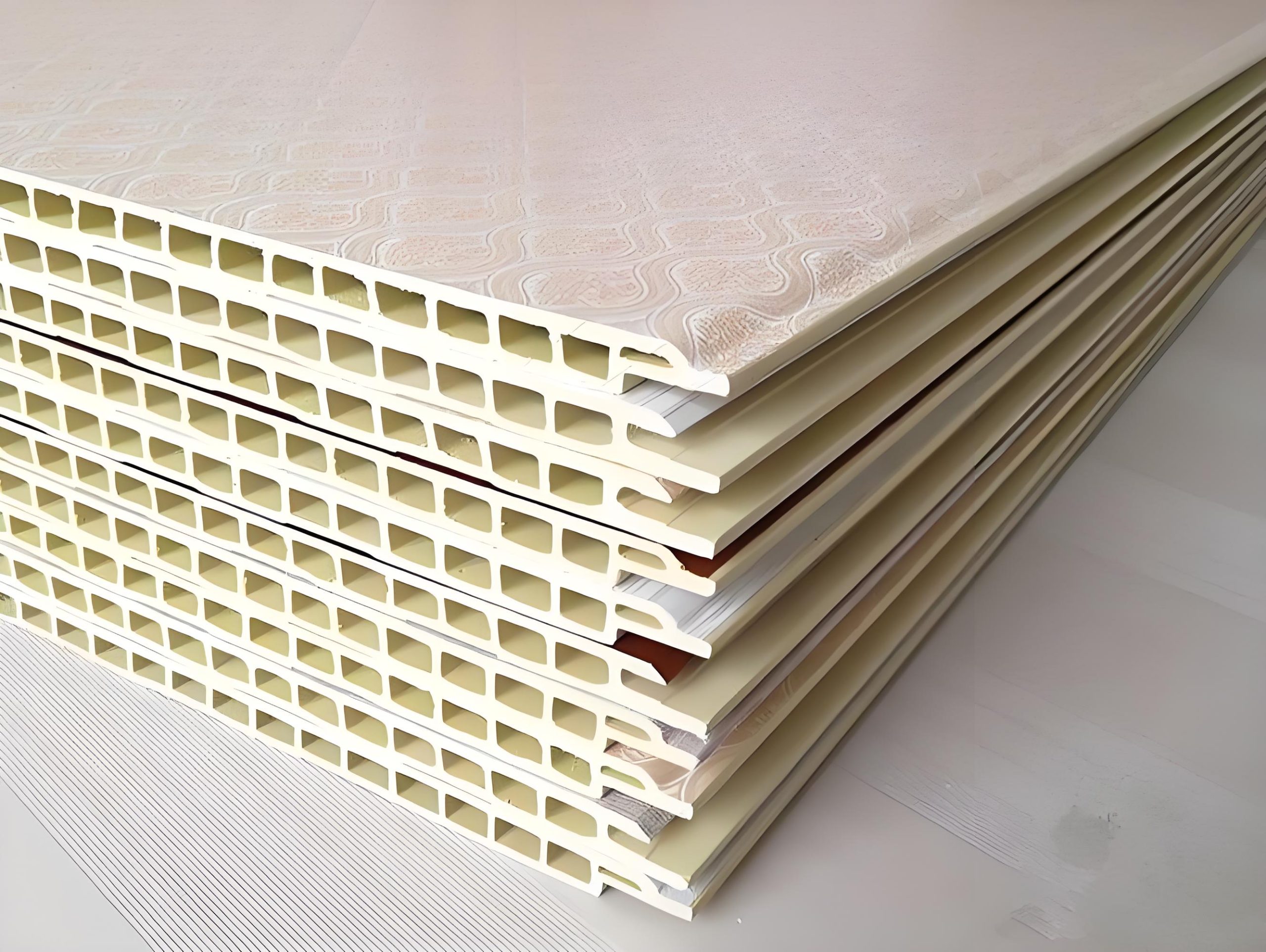

Bamboo and wood fiber wallboard is manufactured by high temperature production extrusion molding, molding, laminating and other processing technology. Its thickness is about 0.9~1 cm, straight outside, the surface covered with PVC resin film, with a variety of styles and shapes, can meet different decorative needs.

In summary, bamboo and wood fiber wallboard is a new composite material that combines the advantages of natural bamboo powder and wood powder, and is supplemented by a variety of materials and processes. It has the characteristics of environmental protection, durability and excellent performance, and is widely used in the field of interior decoration.